Quick Details

Type: Digital Printer

Condition: New

Plate Type: Screen Printer

Place of Origin: Shandong, China (Mainland)

Brand Name: MINGYANG

Model Number: MY1800T/MY3200T

Usage: Bill Printer, Card Printer, Cloths Printer, Label Printer, Paper Printer, Tube Printer

Automatic Grade: Automatic

Color & Page: Multicolor

Voltage: 110V/220V

Gross Power: 12KW max

Dimensions(L*W*H): 2700*2400*1250mm

Weight: 1500 KG

Certification: CE Certification

After-sales Service Provided: Engineers available to service machinery overseas

Product name: Belt Textile Printer

Ink type: all kinds of Ink

Print head: Dx5 *2 /gen5 Print Head *2/8

Color: dual 4 Colors (CMYK)

Application: Indoor

Print speed: 36-260sq.m/h max

Printing width: 1800mm/3200mm

RIP software: Standard MainTop RIP

Print resolution: 1440 *1440 Dpi

Print interface: USB2.0

Flatbed Printer Plate Type and textiles Usage digital inkjet belt textile printing machine

Features

1, Printing width: 1.8m,3.2m

2, Print head: Ricoh GEN 5 heads;

3, Auto belt system, belt cleaning-heating-adjusting system;

4, Glue belt convey way, auto feeding and taking up system;

5, Print direct on all fabrics.

6, Belt system is compatible with Mimaki,Mutoh,Roland,and Chinese brand printers.

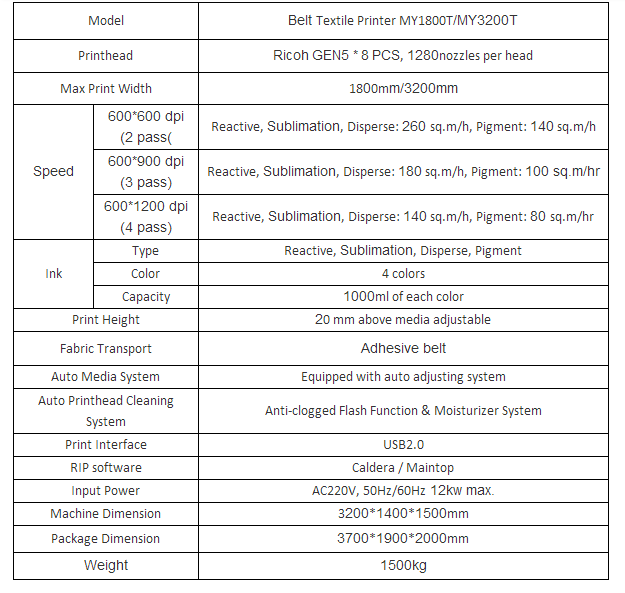

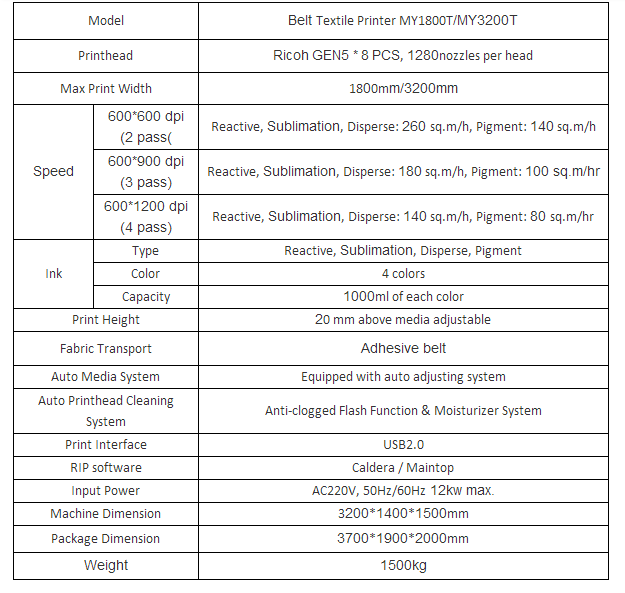

Specifications

Belt conveyor:

*German“SIEGLIN” Conveyor belt specially for digital textile printing , it can work over 10 years.

*Belt system automatically adjusted by Siemens PLC sensor and motor.

*Glue: oil based, prevents fabric dislocation or movement, elastic fabric can be printed as well.

*Front and back Belt shafts diameter to 200mm.

*Bracket props up the belt and makes it smooth.

Belt auto self-clean system:

*2pcs sponge shafts instead of brush to protect the belt better and prolong the glue lifespan.

*Water-cycled pipe to keep the water tank and sponge clean.

*The washing system height is adjustable.

*After washing, the PID controlled drying system can dry the belt effectively.

Feeding and taking up system:

*Auto feeding shaft for fabric roll feeding; special tension bar attached for fabric sheet feeding.

*Silicone cylinder with pneumatic pressure control for fixing the fabric on the blanket.

*Taking up system: taking up convey strength and speed is controllable, according to different fabric adhesive feature.

Our Services

1. Supply 24 hours on-line English technique support and free training.

2. English RIP and print software, free update when new software function launched.

3. 18 months warranty: for the main board, head board and the electricity motor.

4. English users manuals to guide customers install, operate and maintain easily.

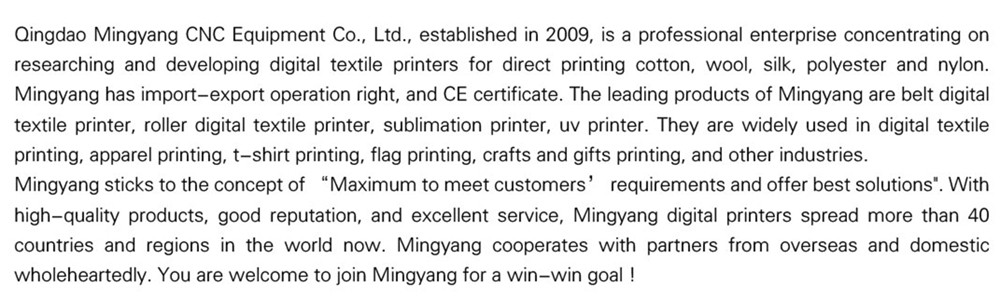

Company Information

Packaging & Shipping

FAQ

1) What is the main parameters of Ricoh printhead?

1280 nozzles per head, fire frequency: binary mode 30khz, grayscale mode 20khz, head native resolution 600dpi.

It supports 2 colors per head, 4 channels per head.

2) How is your after service ?How can we solve any problems?

Oversea installation and technical training service is provided.

24hours online support and parts express service available.

3) What kind of ink should we use?

Sublimation ink: polyester or polyester based blended fabric

Reactive: Cotton, wool, viscose, silk, etc.

Pigment:Cotton, or cotton and polyester blended T-Shirt.

Acid: Silk, wool, nylon, etc.

4) How much does the ink cost per square meter?

The ink consumption is 10ml-12ml/sq. m

5) What about the printer maintenance?

Manual and guidebook will be provided along with the machine.

Any requirements on printer working environment and the surroundings?

Working environment and the surroundings of printer must reach the requirement. (Temperature: 20-25℃, Humidity 50-70%) The surroundings should not have strong magnetic field or equipment that may cause a lot of dust.

<p style="margin-top: 0px; margin-bottom: 0px; padding: 0px; border: 0px; font-style: inherit; font-variant: inherit;

English

English